One of the main environmental impacts when producing jeans is the use of water. Most consumers want to have a pre-washed denim. However, to give your jeans these fades, most washing techniques require a lot of water and chemicals. Fortunately, there has been a revolution when it comes to making your jeans look worn-in.

With two of our denim manufacturers we’re working on the improvement of our washing recipes. With the help of Jeanologia laundry machines we’re measuring and reducing our environmental impact when it comes to water, energy and chemicals. In this blog, we will explain how our manufacturers use laser, ozone and e-flow as new washing techniques to minimize the waste of water and use of energy and chemicals. Each washing technique comes with its own benefits. Let’s dive in!

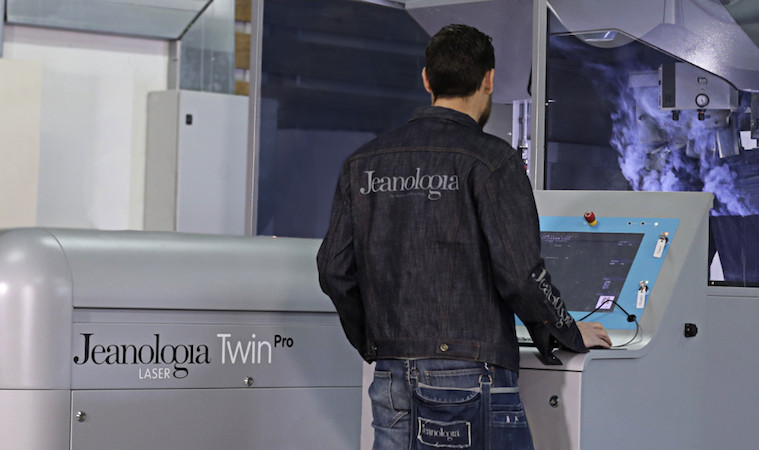

Laser Technique

The laser machine works fairly simple. Instead of using sandpaper or chemicals, a computer burns the fades in the denim. You first design a washing pattern, a design of where and how visible the fades need to be. It is even possible to have an actual image faded into the jeans! This design is transferred to the laser machine, which burns the fades into the jeans.

Reducing the use of water, power and chemicals are not the only benefits of this technique. It also reduces the loss of fabric strength by 50% and increases the efficiency of a workplace by 500%. Even though you might think that burning fades into jeans could cause health issues, this is not the case. The laser does create smoke, but the well-designed ventilation system makes sure you can’t even smell it.

Ozone Technique

Another technology we’re using is Ozone. This machine can be used for instance to replace stone wash. It bleaches the fabric without the use of any bleach & chemicals – or stones for that matter.

Instead of using water this machine uses atmospheric air. The machine first takes in normal air, before turning this air into Ozone. After the machine is filled with Ozone gas, it starts tumbling and gives the garments their natural worn-in look. At the end of the cycle, the machine transforms the Ozone back into air and releases it back into the atmosphere. When using the Ozone technique, water savings are up to 67%, chemical savings up to 85% and power savings up to 62%.

E-Flow Machine

Last but not least there is the E-Flow machine, a technique which uses so-called nanobubbles. It can be used for softening or creating 3d effects without using a lot of water and chemicals. Imagine it like a washing machine filled with steam instead of water. The machine creates up to 1 million bubbles per square centimeter. These air bubbles are made from water and an added product you want to use on the garment. The bubbles transport this product into the garment. With the use of the E-Flow machine, water usage is reduced to only one glass of water per garment. E-Flow saves up to 95% water, 90% chemicals and 40% power.

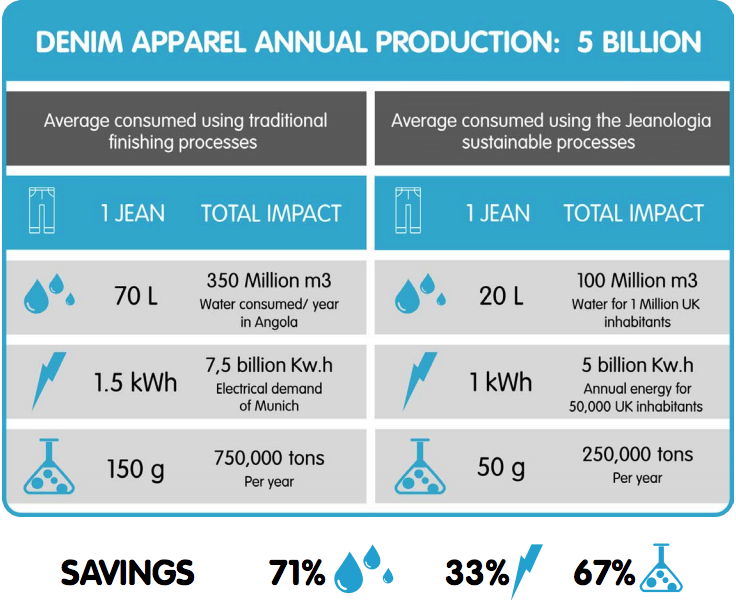

Impact comparison | © Jeanologia Press Kit

Let’s talk numbers

If you ask us, this is the new way of washing. Finishing a conventional pair of jeans normally uses 70 liters of water. Using Laser, Ozone and E-Flow this can be reduced to just 20 liters or less, not to mention the energy and chemical savings.

Besides that, there are some serious health benefits to it as well. These washing techniques reduce the contact between humans and hazardous substances like chemicals. They create a safer work environment for the workers, a lower environmental impact and a cleaner denim for you. That’s why our denim manufacturers Soorty, Sarp & Dinateks use these techniques for the Kuyichi jeans they produce. Read more about our manufacturers on our Pure Production page.

I am in search of 100% cotton denim jeans but can’t find any on your website. Am I wrong, or are all a combination of denim and elasthane? If so, please give thought to offering 100% cotton. I cannot be the only person on the planet who would be glad to find the classic jeans that were once the norm but now seem extinct, at least as far as jeans for women are concerned. Keep up the good work on seeking to save water, toxic dyes, and whatever else you can do to be kind to the plant.

Kind regards,

Pauline

Hi Pauline,

Thanks for your comment and interest in a 100% cotton denim! Unfortunately, at this moment all jeans we offer are a combination of several fabrics. Around July/August we will be launching the Jenna fit in an unwashed 100% cotton denim. We will keep you posted on our social media platforms, the website and our newsletter.

Kind regards,

Thomas.